This month’s Boat Sense column covers something that all Fisherman readers have in common if they keep their boats in the water for more than a week or two – anti-fouling bottom paint. Applying a few layers of anti-fouling bottom paint on the sections of your vessel’s fiberglass or aluminum hull that sit below the water line when resting at the marina between fishing trips will pay dividends in the long run. Bottom paint typically slows or prevents the attachment and growth of marine organisms that can adhere to unprotected fiberglass gelcoat or poorly painted surfaces, which in turn affects your boat’s speed, fuel economy and overall performance.

Changing Times

Back in the good old days, many boaters opted for a hard modified epoxy bottom paint for their ride. This paint is still a popular choice with boaters today and lives true to its name. Once you apply it, only an unscheduled high speed meeting with a sand bar or a trip to the sand/bead blaster can typically take it off. This type of paint is somewhat reasonably priced, features a high degree of pesticides (usually copper) that are located in the surface layer of the paint, but needs to reapplied each season. Hard paints deliver solid protection whether the boat is moving or not when at dockside. On the down side, epoxy based paints don’t wear away and can build up thick layers over time, which an adversely affect boat speed and performance. Eventually, the thick layers of paint have to be brought down to minimal thickness, effectively starting the process all over again. Problems occur when the surface layer of biocide eventually wears away, which allows organisms to attach themselves to sections of the hull below the waterline, robbing you of speed and compromising fuel economy. Hard bottom paint also has a critical time clock that determines its effectiveness. Usually after being exposed to the air for 72hours or longer, the hard epoxy bottom paint oxidizes on the outer surface and becomes totally ineffective, allowing barnacles and other marine life to adhere to the boat’s bottom. Just because you can see the paint, don’t assume that it is working up to speed. Dual resin technology bottom paints are still a variation on the hard paint theme, providing the benefits of both a hard modified epoxy and an ablative self-polishing paint. Although dual tech paints are slow polishing for consistent anti-fouling performance, with a reduced paint build-up over time compared to the modified epoxy products, they are still generally a single season solution and need to be reapplied for the next boating year. The latest versions of the hard bottom paints feature a water base, with correspondingly less volatile organic compounds(VOCs) in the product, which is better for mother earth and make for easier clean-ups.

Back in the good old days, many boaters opted for a hard modified epoxy bottom paint for their ride. This paint is still a popular choice with boaters today and lives true to its name. Once you apply it, only an unscheduled high speed meeting with a sand bar or a trip to the sand/bead blaster can typically take it off. This type of paint is somewhat reasonably priced, features a high degree of pesticides (usually copper) that are located in the surface layer of the paint, but needs to reapplied each season. Hard paints deliver solid protection whether the boat is moving or not when at dockside. On the down side, epoxy based paints don’t wear away and can build up thick layers over time, which an adversely affect boat speed and performance. Eventually, the thick layers of paint have to be brought down to minimal thickness, effectively starting the process all over again. Problems occur when the surface layer of biocide eventually wears away, which allows organisms to attach themselves to sections of the hull below the waterline, robbing you of speed and compromising fuel economy. Hard bottom paint also has a critical time clock that determines its effectiveness. Usually after being exposed to the air for 72hours or longer, the hard epoxy bottom paint oxidizes on the outer surface and becomes totally ineffective, allowing barnacles and other marine life to adhere to the boat’s bottom. Just because you can see the paint, don’t assume that it is working up to speed. Dual resin technology bottom paints are still a variation on the hard paint theme, providing the benefits of both a hard modified epoxy and an ablative self-polishing paint. Although dual tech paints are slow polishing for consistent anti-fouling performance, with a reduced paint build-up over time compared to the modified epoxy products, they are still generally a single season solution and need to be reapplied for the next boating year. The latest versions of the hard bottom paints feature a water base, with correspondingly less volatile organic compounds(VOCs) in the product, which is better for mother earth and make for easier clean-ups.

A Polished Approach

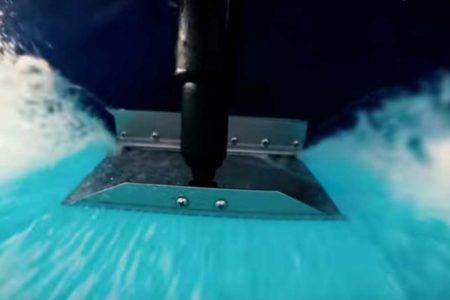

Ablative and polishing bottom paints solve the problem of layer buildup over time, in addition to offering protective biocides throughout their layers, not just on the surface. Ablative antifouling coatings wear away when the boat is moving, so there will be less paint build up over time, offering multi-season protection. However, these have the potential to “ablate” in high-wear areas or on boats that are frequently used at higher speeds. Polishing bottom paints are formulated to wear away at a controlled rate like a bar of soap over time, providing steady and reliable protection throughout the life of the coating. These can be hauled and relaunched without repainting each season, so they qualify as being multi-seasonal. The antifouling protection is dependent on the thickness of the coating. Polishing paints also get smoother over time delivering better hull and fuel efficiencies.

Water-based anti-foulings utilize water instead of traditional solvents as the mechanism to apply the paint. These “aqua” based products range from single to multi-seasonal and in different hardness levels from ablative to hard coatings. Water based bottom coatings offer similar performance to traditional solvent based anti-foulings and are easier to clean up. Their low odor allows them to be applied indoors or outdoors. The dark side of water-based bottom paints are that they tend to be slower-drying if humidity levels are high and might dry too fast in hot and dry conditions.

Low VOC/High Solids bottom paints employ more resin in the paint make up and less solvent to the chemistry of the coating. This can also reduce the VOC in the coating for use in areas that have VOC restrictions. The High Solids nature of the products also means that a thicker coat is applied, which provides longer protection. Specialty paints are typically the racing finishes that are hard and burnishable (wet sanded) to give a smoother finish to the antifouling paint. The added thickness of this type of paint makes it more of a challenge to roll-apply to the hull, it requires sanding to smooth out and generally offers one-to-two seasons of protection.

Latest Trends

The engineers that I spoke to at Interlux (AkzoNobel) and Pettit mentioned that there is a trend in the industry to go with more ecologically-friendly bottom coatings. According to Matt Anzardo, the North American Marketing Manager for AkzoNobel Yacht, “There is a trend towards using more water-based anti-foulings, which are easy to apply, with easy clean up and low odor. Interlux is unique in that we have a wide range of water-based anti-foulings that offer single to multi-seasonal antifouling protection that are either in a hard or polishing resin matrix. These products deliver solid antifouling protection and are easier on the environment. California has instituted a leach rate amount that limits the amount of copper that can be released from the coating. Currently Washington State has a rule that bans the use of copper based anti-foulings, which is expected to go into effect in 2021, but they are analyzing a new study that may change this rule.”

Professional Advice

When I asked Matt Anzardo if he had any preparation or application tips/tricks and could recommend when was the best time to paint a boat’s bottom, he replied, “First and foremost, ensure that the antifouling paint you are applying is compatible with your existing coating and be aware of what type of prep is required to apply the new coating. You will want to also check the integrity of the existing coating to make sure there are no chips or gouges, which should be addressed before you paint. Once this is done, you want to use the recommended roller like a 3/8-inch nap for most antifouling paints and brushes that are solvent-resistant. Bargain foam rollers and brushes found in big box retailers are generally not recommended for anti-fouling paint, as they generally do not put on the proper amount of paint or may fall apart during the application, due to the solvent degradation. The bottom paint needs to be applied at the recommended thickness to deliver the proper anti-fouling protection. The majority of boaters bottom paint in the spring before launching, but with the multi-seasonal paints like Micron Extra or Micron CSC, you can also apply these in the fall and get a head start on the spring prep chores. You will want to start painting in the morning, so that the coating has the remaining part of the day to dry. Most of Interlux products can be applied at 41degrees or higher, which gives boaters more flexibility to paint in the early spring, compared to most other products that require a minimum of 50 degrees or higher. You will want to follow the over-coating and launching instructions on the label to get the best results from your bottom paint. Make sure you save some paint for the pad and block areas on the hull, which should be painted before you launch.”

Compatibility Problems

Before you apply an antifouling paint over a previously coated surface, you will want to read the instructions and check the compatibility chart to understand what the necessary prep steps are before you start. Generally speaking, a polishing anti-fouling paint can be applied over a hard anti-fouling; however a hard paint may not be compatible over an existing polishing or ablative coating. It’s always best to consult the manufacturer’s chart or contact their technical department to find out the needed prep steps to apply.

How Do You Remove Old Bottom Paint?

Interlux’s Matt Anzardo had some sage advice for this dreaded of all boating chores. According to Matt, “The best way to remove old paint is to have a professional do it, but there are a couple of ways that a professional can make this happen. The most popular way to remove the old anti-fouling paint is to use a blasting medium such as recycled glass or baking soda (the baking soda needs to be flushed with freshwater when the blasting is completed to neutralize the PH from the baking soda). The other way is sanding it off by hand, but you want to make sure you can capture the sanding residue and dispose of it properly. If you are going to remove the paint, then it is recommended that you do it in the fall months when you haul out, so that way you can do a full inspection of your running bottom. If there is moisture in the hull (osmotic blisters), it allows some time for the hull to dry out over the winter and then you can apply the barrier system like InterProtect 2000E and then an antifouling paint like Micron Extra or Micron CSC.”

Some Closing Thoughts

Bottom painting is a real pain but there are steps that you can take to make it more tolerable. I once made the mistake of having a “professional” sand-blast the multiple layers of hard epoxy off of my old Phoenix 27. Unfortunately the operator was only “semi-professional” and had a heavy hand on the gun, scoring my bottom with hundreds of pock marks. He claimed that this was “osmotic blistering” but my guess was that he was still learning his trade, or maybe should have employed a softer medium like plastic beads or walnut shells. I spent 50+ hours filling these holes with a waterproof vinyl-ester 3M compound and then fairing the bottom with a hand-sander, before putting on three layers of an (InterProtect 2000E) epoxy barrier coat and then two subsequent layers of an ablative bottom paint (Micron CSC). I never had an issue with the bottom or the paint ever again after that.

Bottom painting is a real pain but there are steps that you can take to make it more tolerable. I once made the mistake of having a “professional” sand-blast the multiple layers of hard epoxy off of my old Phoenix 27. Unfortunately the operator was only “semi-professional” and had a heavy hand on the gun, scoring my bottom with hundreds of pock marks. He claimed that this was “osmotic blistering” but my guess was that he was still learning his trade, or maybe should have employed a softer medium like plastic beads or walnut shells. I spent 50+ hours filling these holes with a waterproof vinyl-ester 3M compound and then fairing the bottom with a hand-sander, before putting on three layers of an (InterProtect 2000E) epoxy barrier coat and then two subsequent layers of an ablative bottom paint (Micron CSC). I never had an issue with the bottom or the paint ever again after that.

I have opted for the multi-season protection of the polishing ablative paints and now employ Micron WA to leach less VOCs into our coastal waterways. Most major bottom paint manufacturers like Interlux and Pettit offer a wealth of advice and videos on their websites. West Marine is also a great source for anti-fouling intel and they offer both article and videos on the topic. Painting your boat’s bottom is a perfect do-it-yourself project, but if you disagree, you can always take it down to your local boatyard and let the professionals make it happen.